RESPONSIBLE CARE

RESPONSIBLE CARE

Responsible Care (RC) activities refers to activities whereby businesses that handle chemical substances voluntarily ensure “environment, safety and security” in all processes from the development of chemical products through to manufacturing, distribution, use, final consumption, and disposal, disclose the results of these activities, and engage in dialogue and communication with society. In other words, RC is a self-management activity for the environment and to ensure safety throughout the life of a product.

At Air Water Performance Chemical, we actively promote Responsible Care (RC) in the fields of occupational safety and health, environmental protection, safety and disaster prevention, quality assurance, chemical and product safety, distribution safety, and dialogue with society.

RC Basic Policy

Air Water Performance Chemical recognizes Responsible Care (RC) as an important management issue and promotes RC activities around the seven pillars of “occupational safety and health,” “environmental protection,” “safety and disaster prevention,” “quality assurance,” “chemical and product safety,” “distribution safety,” and “dialogue with society.”

Various RC Initiatives in Business Activities

Occupational Safety and Health

Every day we strive to prevent similar accidents and recurrences based on lessons learned from the past, such as by developing an environment where employees can work safely. In addition, we conduct 5S (Sort, Set in Order, Shine, Standardize, and Sustain), safety and health risk assessment, Hiyari-Hatto (close call), safety and health education, and the sharing of Group safety information.

Environmental Protection

We engage in various environmental protection activities that reduce the environmental impact of our business activities, such as the prevention of air and water pollution, reduction of environmental impact, and reduction of waste generation.

These photos show a CPS DOWTHERM heating furnace which is currently operating on gas (left) and an exhaust gas combustion facility to reduce PRTR substance emissions, both parts of the conversion of fuel for boilers and other equipment to gas (Kawasaki Plant).

-

CPS DOWTHERM heating furnace

-

Exhaust gas combustion facility

Safety and Disaster Prevention

Every plant has established and is operating a disaster prevention system in the event of an industrial accident, large-scale earthquake or other emergency in order to ensure the safety of local residents and employees.

Quality Assurance

All of our offices have acquired the ISO 9001 certification, which is the international standard for quality management systems, and promote quality management and quality improvement activities. In addition to ensuring compliance with regards to our products and services, we are also striving to further improve quality while also improving our facilities and the level of quality management in order to promptly and reliably meet the quality requirements of our customers.

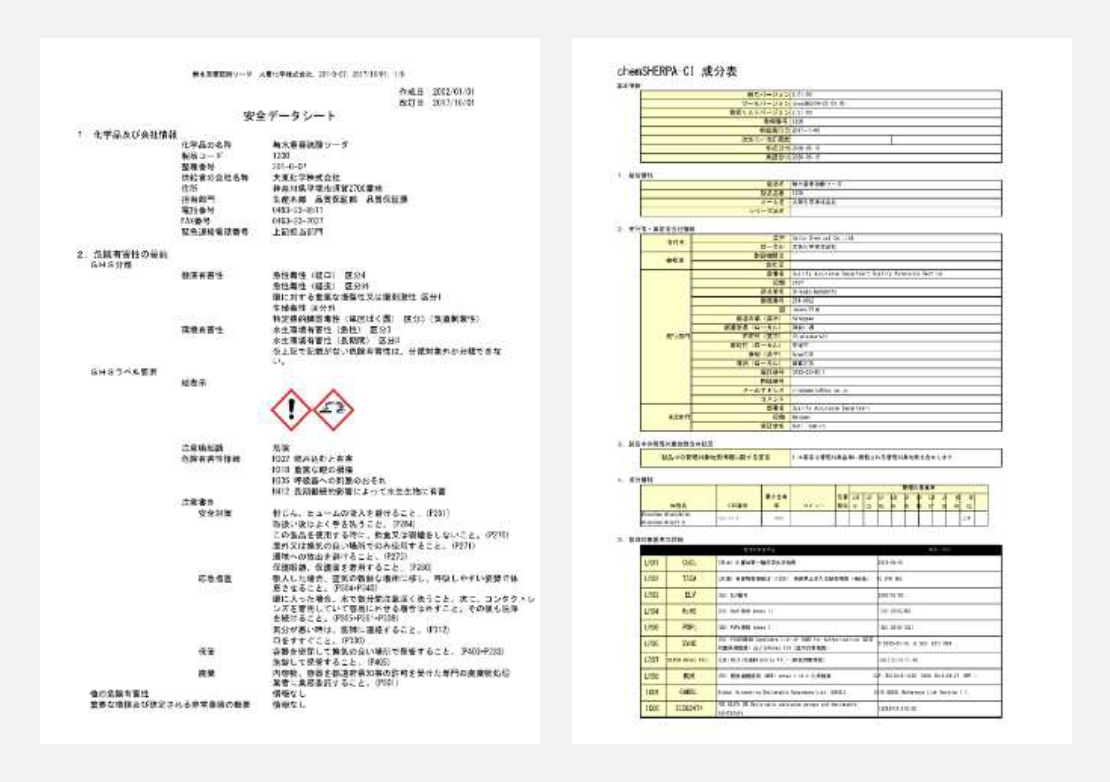

Chemical and Product Safety

To ensure the safe handling of our products, we provide safety data sheets (SDS) and hazard and toxicity information. In addition, we provide “chemSHERPA” to communicate information on the chemical substances contained in our products.

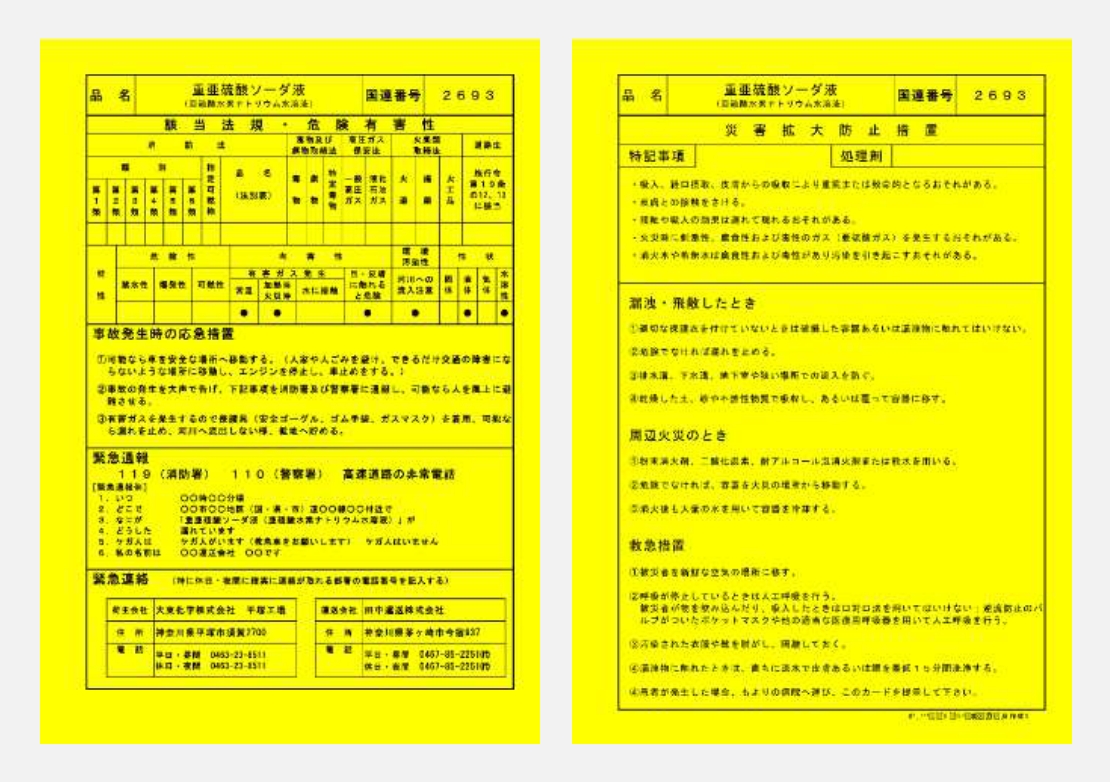

Distribution Safety

To prepare for any accidents that may occur during the transportation of chemicals, we provide emergency contact “Yellow Cards” to transporters. This contact card contains information on safe handling that can be used by transporters, police, firefighters and others involved in the handling of accidents.

Dialogue with Society

Amongst the various stakeholders that are involved with our company, we place particular importance on our relationship with local communities. In order to contribute as much as possible to local communities, each of our plants continue to carry out the following activities.

At Kawasaki Plant, we conduct cleanup activities in the area around the plant as part of our local volunteer activities.

At Shonan Plant, we deepen our community interaction by holding an annual “Summer Festival” and planting tulip bulbs by the Sagami River with local elementary school children as a member of the “Hiratsuka District Environmental Measures Council.”

At Shizuoka Plant, we participate in beautification activities and the Japanese rice fish business, and contribute to the beautification of the local environment through the “Niino and Osa Rivers Conservation Association”