RESEARCH & DEVELOPMENT

RESEARCH & DEVELOPMENT

Fusing the Technologies and Expertise of Three Companies to Produce Deeper Functionality and Greater Added Value

Air Water Performance Chemical Inc. (AWPC) that meets customer needs for a wide range of functional chemicals, primarily centered on electronic materials. We do this through our research and development strengths, which combine and strengthen the wide range of technologies and expertise independently cultivated by each of the three predecessor companies.

Our goal is to meet customer needs in a timely fashion and offer unique proposals that help customers take on new challenges. To achieve this, we engage in a broad range of research and development activities, from new product and application development to production process development and factory technical support.

We create materials and technologies that contribute to the realization of sustainable societies throughout the world as we pave the way for new fields and value.

Research and Development Policy

Enhancing the power of chemicals through our new corporate structure - Supporting industry and peoples' lives

We perform unique development work to create essential "added value chemicals." By leveraging the advanced synthesis technologies we have accrued through the years and our expansive range of business fields, we focus on developing fine chemical products, such as electronic materials and battery materials, that meet the needs of advanced industries. This development enables us to satisfy our customers' diverse material development needs.

Becoming an indispensable company for Smart Societies

In the near future, our societies will become ultra-Smart Societies. The world of the IoT, in which everything is connected via the internet, will require fast, high bandwidth communications. To achieve this, it will be essential to further increase signal frequencies. Relaying those signals without loss will require even lower permittivity and higher thermal resistance.

We are developing materials with ultra-high thermal resistance and ultra-low permittivity for use in 5G systems, the next generation of ultra-fast mobile telecommunication systems, and the 5.5G and 6G systems that will follow.

Technologies that can contribute throughout the world

One of our strengths is oxidation technology. Making full use of this, we have developed our own catalysts and processes for producing naphthoquinone (1,4-Naphthoquinone), which is an intermediate product of naphthalene oxidation reactions, with high purity and high yield. Through this, we have succeeded in mass producing naphthoquinone. By using naphthoquinone as a raw material, we are currently utilizing our advanced synthesis technologies and developing new quinone derivatives with new functions. Quinone derivatives are polycyclic aromatic functional materials with naphthalene or anthracene backbones, which boasts unique properties, especially oxidation-reduction, bioactivity, optical absorption, radical capture, and heat and flame resistance properties.

Our Technologies

Oxidation technologies

Catalytic gas phase oxidation (fixed bed)

- Vanadium oxide catalyst development/evaluation

- Vanadium oxide catalyst manufacturing technologies

- Vanadium oxide catalyst operation control technologies

Liquid-phase oxidation

- Hydroquinone liquid-phase oxidation

- Technologies for oxydesulfurization of hydrogen sulfide using desulfurization catalysts (NQS®)

- Electrolytic oxidation technologies

- Liquid-phase air oxidation

- Oxidative coupling reactions

Liquid-phase air oxidation

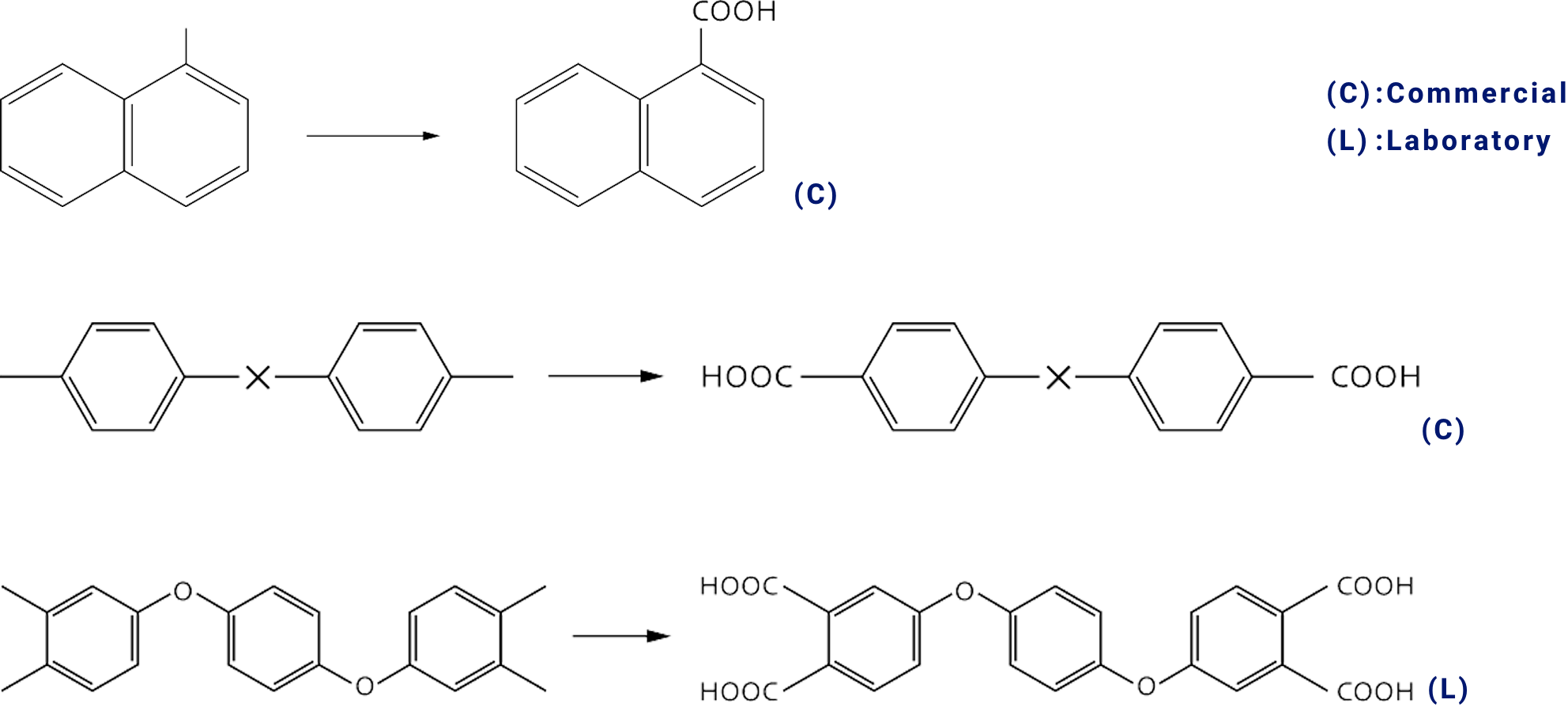

Liquid-phase air oxidation is a core technology that uses special equipment and uses the oxygen in the air as an oxidizing agent.

It has a long track record of use for supplying a wide range of carboxylic acid derivatives.

We also use this technology to supply distinctive functional polymer materials.

Characteristics

- Environmentally friendly oxidation method that uses the oxygen in the air as an oxidizing agent

- Unlike chemical oxidation, it can be used to perform synthesis using a small amount of catalyst

- AWPC has special equipment

- AWPC has extensive experience in avoiding explosion limits

Reduction technologies

Catalytic gas phase reduction

- Reductive desulfurization technologies that use hydrogenated reduction catalyst

Liquid-phase reduction

- Catalyst reduction technologies that use hydrogenated reduction (Pd catalyst)

- Reduction technologies that use hydroquinone

- Technologies for reduction, separation, and collection of trace amounts of precious metal ions in water

Synthesis technologies

Organic acid derivatives

- Manufacture of organic acid derivatives (esterification, transposition, and hydration reactions)

- Manufacture of polyester polyol (Maximol®)

Quinone derivatives

- Naphthoquinone and anthraquinone manufacturing

- Manufacturing of quinone active ingredients for agrochemical uses (organic fine chemicals)

- Quinone derivative synthesis technology

Hydroquinone derivatives

- Manufacturing of dialkoxyanthracene

- Synthesis of polycyclic aromatic diol derivatives (alkoxy group, acrylate group, glycidyl group, etc.)

Low-permittivity material development

- Acid anhydride derivative synthesis technologies

- Coupling reaction technologies

- Phenol curing agent design and synthesis technologies

Low-permittivity material development

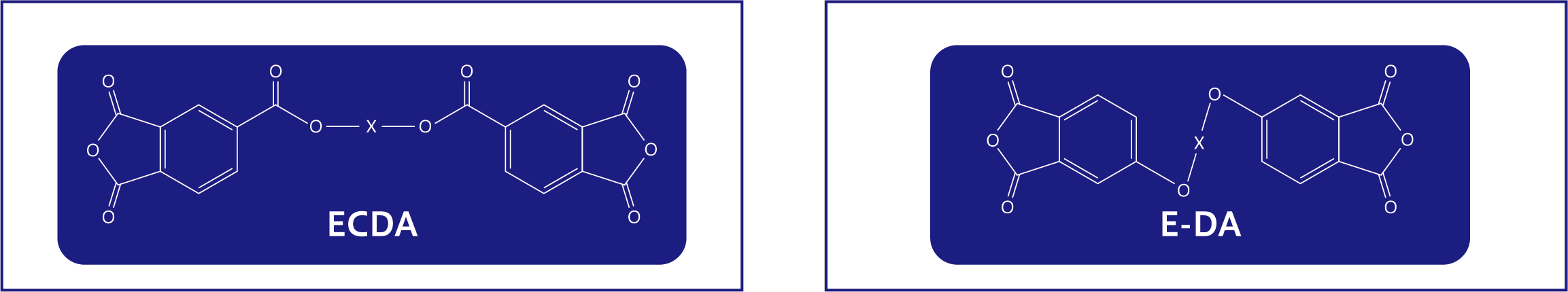

Advances in ICT have created a greater need for materials that can be used at high frequencies, and for dielectric materials that can be used as insulators. Since 2000, we have been developing acid anhydride for polyimide use. We have used our expertise with liquid-phase air oxidation and coupling reactions to develop acid dianhydride for low dielectric polyimides.

We have also leveraged our phenol curing agent design technologies, one of our strengths, to develop curing agents for epoxy resin package substrate build-up film that are highly heat resistant while offering low dielectric dissipation factors. They are also used in other applications, such as low dielectric substrates, as functional resins for electronic materials.

Polymide Monomers

Air Water Performance Chemical supplies polyimide materials containing ester-linked materials, ether-linked materials and/or fluorine.

| Product name | CAS No. | Structural formula | Application |

|---|---|---|---|

| TMHQ | 2770-49-2 | Polyimide monomer (dianhydride) Expected effects: Low CTE, low water absorbency |

|

| TMBPA | 2770-50-5 | Polyimide monomer (dianhydride) Expected effects: Impartation of transparency, solvent solubility |

|

| 6F-BPADA | 61778-79-8 | Polyimide monomer (dianhydride) Expected effects: Impartation of low dielectric, adhesiveness, toughness, low water absorbency |

|

| HQDA | 17828-53-4 | Polyimide monomer (dianhydride) Expected effects: Impartation of adhesiveness, toughness |

|

| SFDA | 167887-55-0 | Polyimide monomer (dianhydride) Expected effects: Impartation of transparency, low CTE, low water absorbency, solvent solubility |

We can also make acid dianhydride monomers to order. We're waiting to hear from you.

Patents

(1) Patent 5280115 "Method for producing p-phenylenebis (trimellitic acid monoester anhydride)"

(2) Patent 5432605 "Method for producing aromatic carboxylic acid dianhydride with ester radicals"

(3) Patent 5525216 "Method for producing trimellitic anhydride diester"

Evaluation technologies

Application development and evaluation (quinone compounds)

- Photo-sensitizer (cationic/radical) evaluation

- Polymerization inhibitor evaluation (preservation stabilizer/process inhibitor)

- Aromatic acrylate group (refractive index /transmittance, heat resistance, light resistance)

- Quinone compound analysis and identification

Application development and evaluation (organic acid compounds)

- Development of urethane raw material (polyesterol)

- Evaluation of rigid urethane/non-foaming urethane

- Foaming speed, formation, and properties (flame resistance/heat resistance/mechanical strength, etc.)

Industrialization technologies

Process proposals

Molecular design technologies

Safe formulation design through calorimetric measurement

Development using inline analysis equipment

Powder characteristic control technologies

Contaminant reduction technologies

- Refinement technologies, closed equipment systems, work environment management systems, etc.

Pulping delignification technologies

- Pulp delignification equipment and delignification agent (SAQ®) evaluation technologies

- Evaluation/analysis technologies of pulp delignification process

- Electrolytic oxidation-based polysulfide manufacturing and analysis technologies

Pulverizing technologies

- Technologies for creating highly concentrated aqueous quinone compound slurries

Deodorization technologies

- Technologies for suppressing the generation of hydrogen sulfide by sulfate-reducing bacteria

- Technologies for oxidizing deodorization of sulfur-based malodorous substances

Collaboration with academia

Development of innovative production technologies

Joint research with The University of Tokyo

Since 2018, AWPC has been engaging in joint research with The University of Tokyo regarding the manufacturing of fine chemicals and continuous flow processes.

Fine chemical production processes are primarily focused on batch production methods, in which all of the raw materials are fed into a reaction tank, and when all reactions are finished, the resulting products are removed from the tank. Unlike the batch method, with the flow method, starting material is continuously pumped in from the end of a reaction column and products are continually fed out of the other end.

The flow method has a higher level of energy productivity than the batch method and produces less waste product, so hopes are high that it will contribute to manufacturing innovation in sustainable societies that seek to achieve green sustainable chemistry (GSC).

AWPC has dispatched researchers to The University of Tokyo with the aim of practically realizing innovative production processes.

We are also engaged in open innovation aimed at rapidly deploying these flow technologies in actual production. Specifically, we are engaging in R&D and practical application efforts through industry-academia-government collaboration such as FlowST*1 and the Ministry of Agriculture, Forestry and Fisheries' Council of Industry-Academia-Government Collaboration (Field for Knowledge Integration and Innovation)*2.

*1

The "Flow Science & Technology consortium," established by the National Institute of Advanced Industrial Science and Technology (AIST).

FlowST provides a space for industry-academia-government collaboration related to flow precision synthesis technologies. It aims to stimulate research efforts and create new innovation. AWPC has participated in this project since August 2017.

*2

"Field for Knowledge Integration and Innovation" was established in 2016 with the aim of industry-academia-government collaboration and open innovation in the fields of agriculture, forestry and fisheries and food. We joined the Council in August 2017 and are taking part in the "R&D Platform of Innovative Production Process for Realizing Low-Price Agricultural Chemicals" and are promoting R&D and practical application with 15 members.

Photo-sensitizer development

Joint research with Yokohama National University

For the creation of higher performance photosensitizers, we have been conducting joint research with Yokohama National University since 2015, in order to demonstrate the synergy effects of the university's abundant knowledge and high analytical capabilities brought about by their sophisticated computer experiments and our production capabilities as well as evaluation techniques putting importance on customer’s perspective especially in photo-curing materials. We have applied for an international patent based on the outcome of the elucidation of the photosensitization mechanism and optimized molecular design while we are widely disseminating our technology through publications and conference presentations.

Detailed photosensitizer, ANTHRACURE® series View MoreOur equipment

Photoanalysis

- Inductively coupled plasma emission spectrometer (ICP-AES)

- Atomic Absorption Spectrophotometer (AA)

- Infrared spectrophotometer (FT-IR microscope)

- Ultraviolet-visible spectrophotometer (UV-VIS)

- Laser-scattering particle size analyzer

- In-line particle profiler (FBRM)

- In-line microscope (PVM)

- In-line FT-IR (React IR)

- Color difference meter

- Refractometer

- Turbidity meter

Electromagnetic analysis

- Nuclear magnetic resonance device (NMR)

- Liquid Chromatography Mass Spectrometry (LC-MS)

- Gas Chromatography Mass Spectrometry (GC-MS)

- X-ray diffractometer

- Fluorescent X-ray analysis device (EDX)

- Scanning Electron Microscope (SEM)

Thermal analysis

- Reaction Calorimeter (RC-1)

- Differential Scanning Calorimeter (DSC)

- Thermogravimetry/differential thermal analysis device (TG-DTA)

Separation analysis

- Gel Permeation Chromatography (GPC)

- Gas Chromatography (GC)

- Ion Chromatography (IC)

- High performance liquid chromatography (HPLC)

Specialized measurement equipment

- Viscometer (B-type, E-type)

- Automatic surface tension balance

- Melting Point apparatus

- Automatic potentiometric titrator

- Conductometric Analyzer

- Water content measurement device

- Dynamic intensity measuring device

- Dynamic viscoelasticity measuring device (DMA)

- Ultraviolet irradiation dynamic viscoelasticity measuring device (Photo-Rheometer)

- Ultraviolet irradiation FT-IR

- Ultraviolet irradiation differential scanning calorimeter (Photo-DSC)

- Laser displacement meter

Evaluation equipment

- Bacteriostatic inspection room (BSL2)

- Urethane foaming and molding test equipment

- Pulp delignification test equipment

- Batch ultraviolet irradiation equipment

- Belt conveyor ultraviolet irradiation equipment

- Light resistance test equipment

Prototyping equipment

- Pilot prototyping equipment

- Catalyst intermediate testing equipment