PRODUCT

PRODUCT

ANTHRACURETMseries

ANTHRACURE™ UVS series

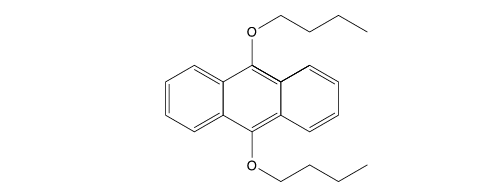

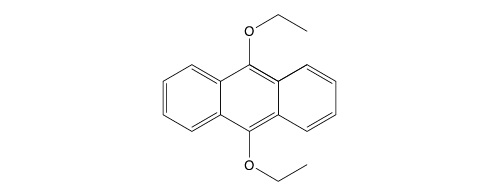

- UVS-1331

- UVS-1101 CLOSE

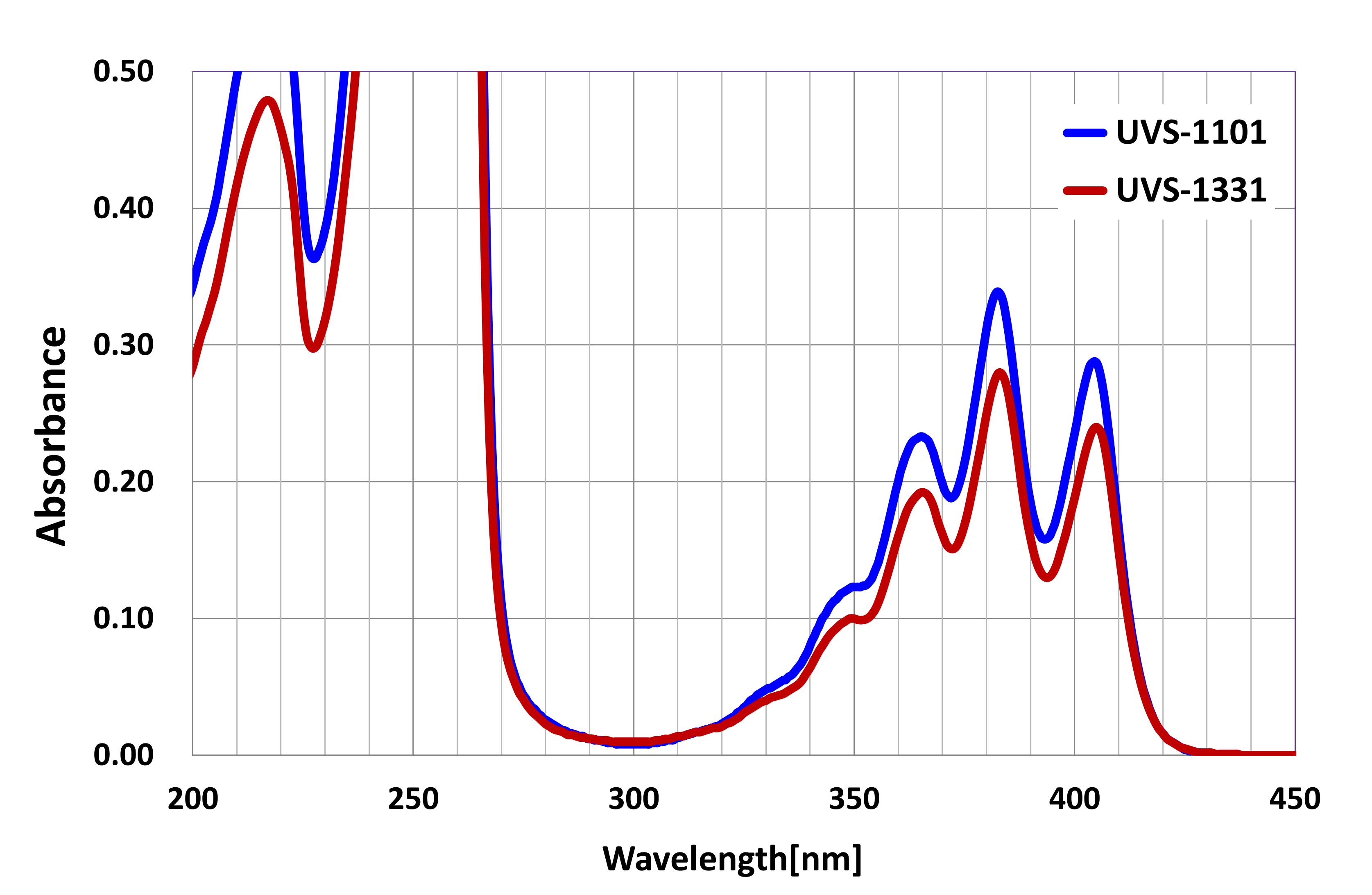

Sensitize photo-initiator in the range from 350 to 405nm

Both UVS-1331 and UVS-1101 show almost the same sensitivity because of those similar chemical structure and its absorption range

Provides improved curing speed, depth of cure or both

Compatible with various light sources such as LEDs

Sharp on/off cut-off performance in radical system

| Product name | ANTHRACURE™ UVS-1331 | ANTHRACURE™ UVS-1101 |

| Structural formula |

|

|

| Molecular formula |

C22H26O2 | C18H18O2 |

| Swiss Ordinance SR 817.023.21 |

Part B | Part B |

| Delivery Unit | 25kg | 20kg |

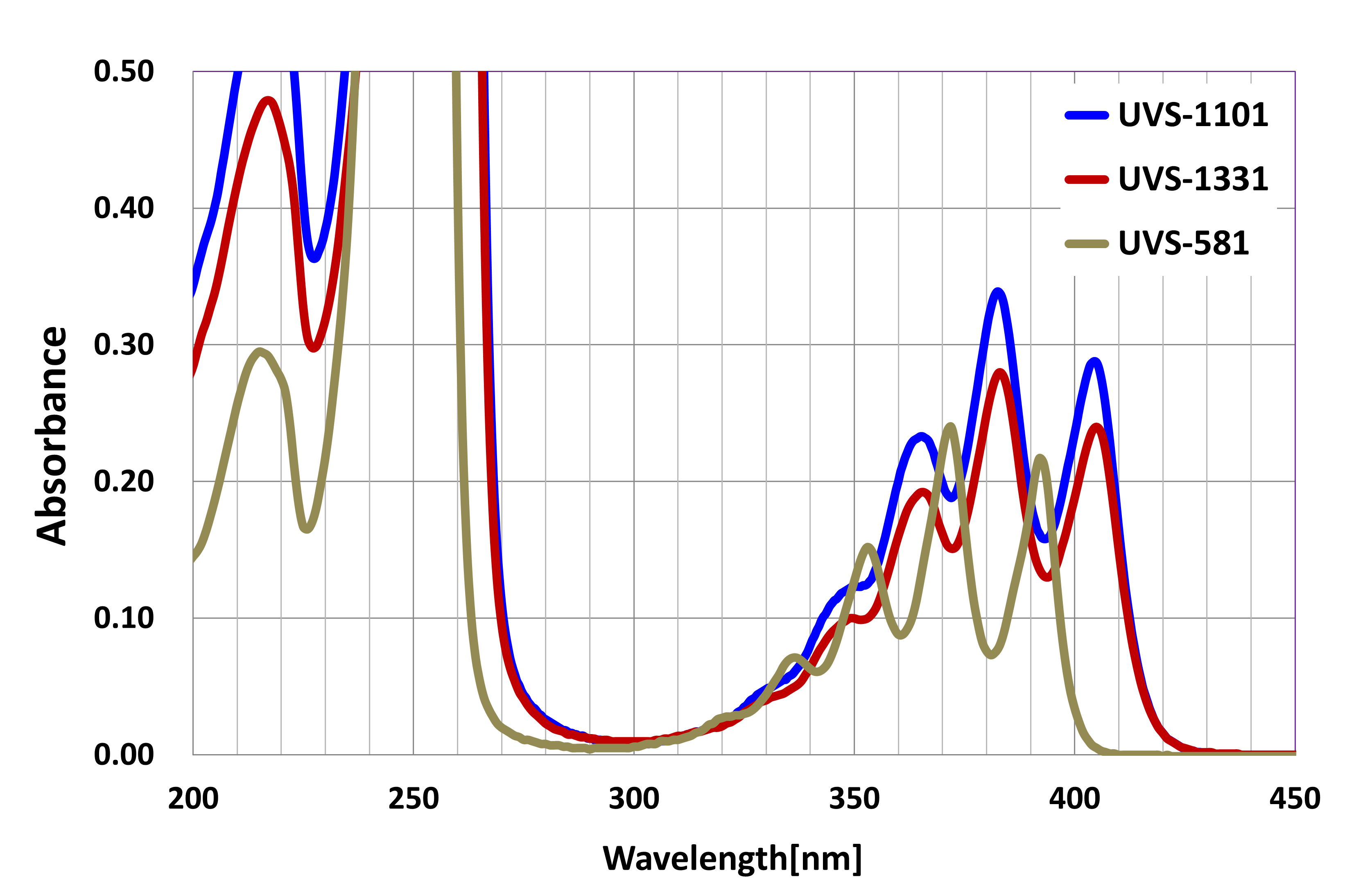

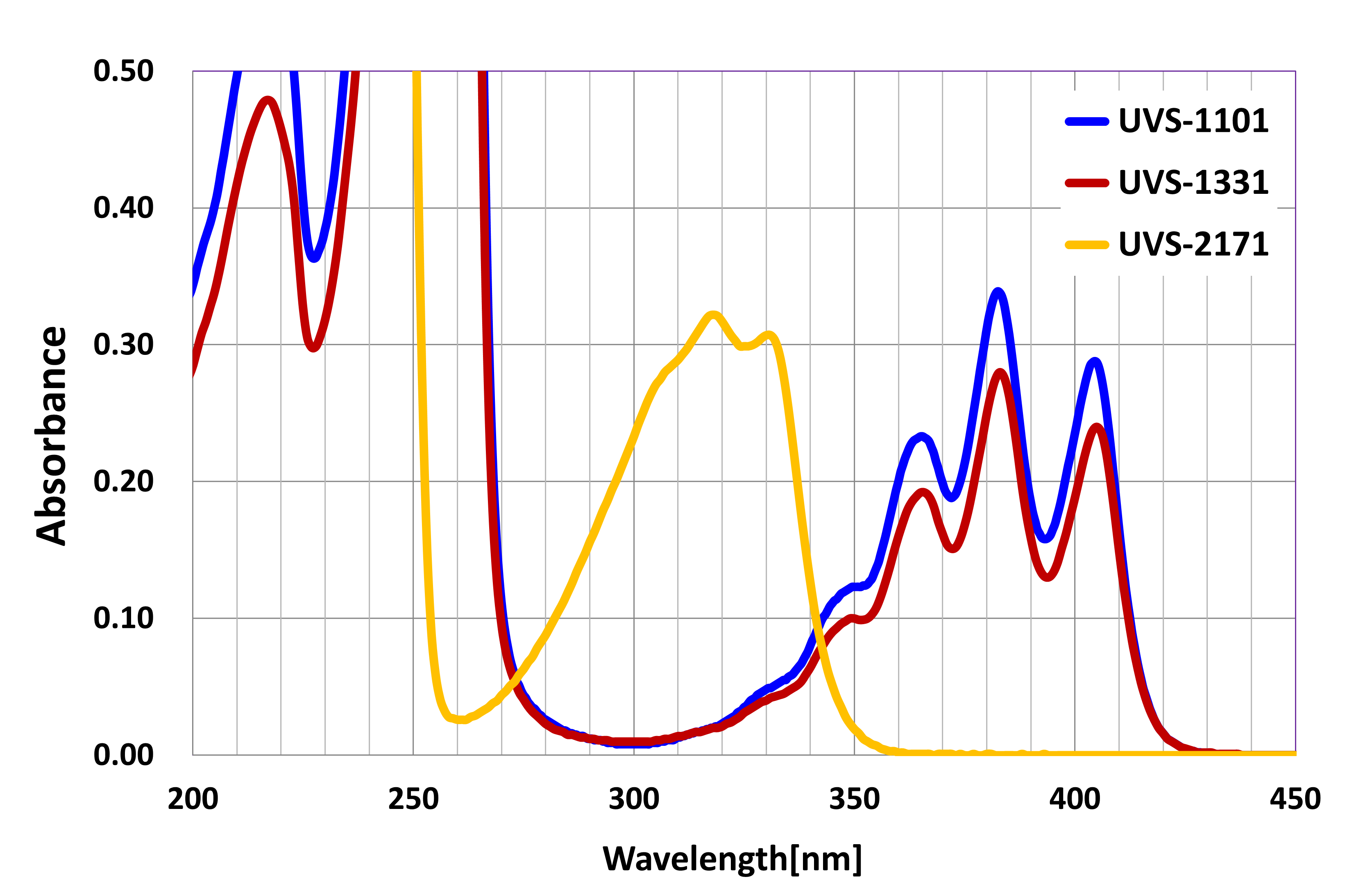

- UV-Vis Spectrum Chart

Concentration : 10 ppm in CH3CN

Optical path length : 10mm

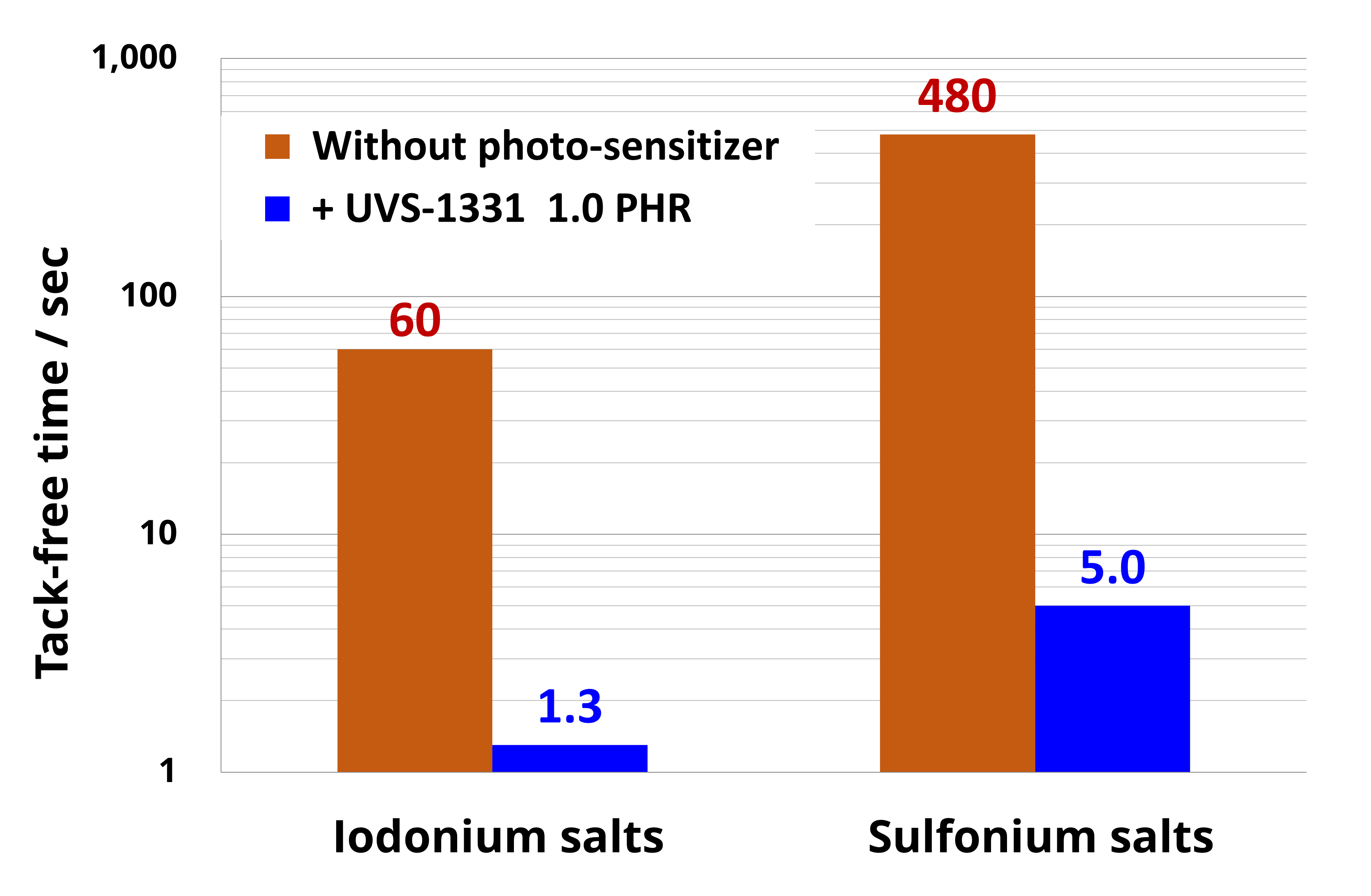

- Improving curing rate

UVS-1331 sensitizes and activate photo-initiators that do NOT show a sufficient performance under long

wave UV-LED such as 365nm, 385nm, 395nm and 405nm.

In addition, UVS-1331 accelerates curing rate

compared with onium salts alone. UVS-1101 shows a similar result as well.

<< Formulation>>

- Monomer:

- Celloxide 202P *1 100 parts

- Photo-initiator:

- Omnicat 250 *2 4 PHR (as Iodonium salts) or CPI-100P *3 6 PHR (as sulfonium salts)

- Photo-sensitizer:

- none or ANTHRACURE UVS-1331 1.0 PHR

Curing condition

Light source :

395nm UV-LED

Intensity : 50 mW/cm2

*1 : Daicel Corporation *2 : IGM Resins B.V *3 : San-Apro Ltd.

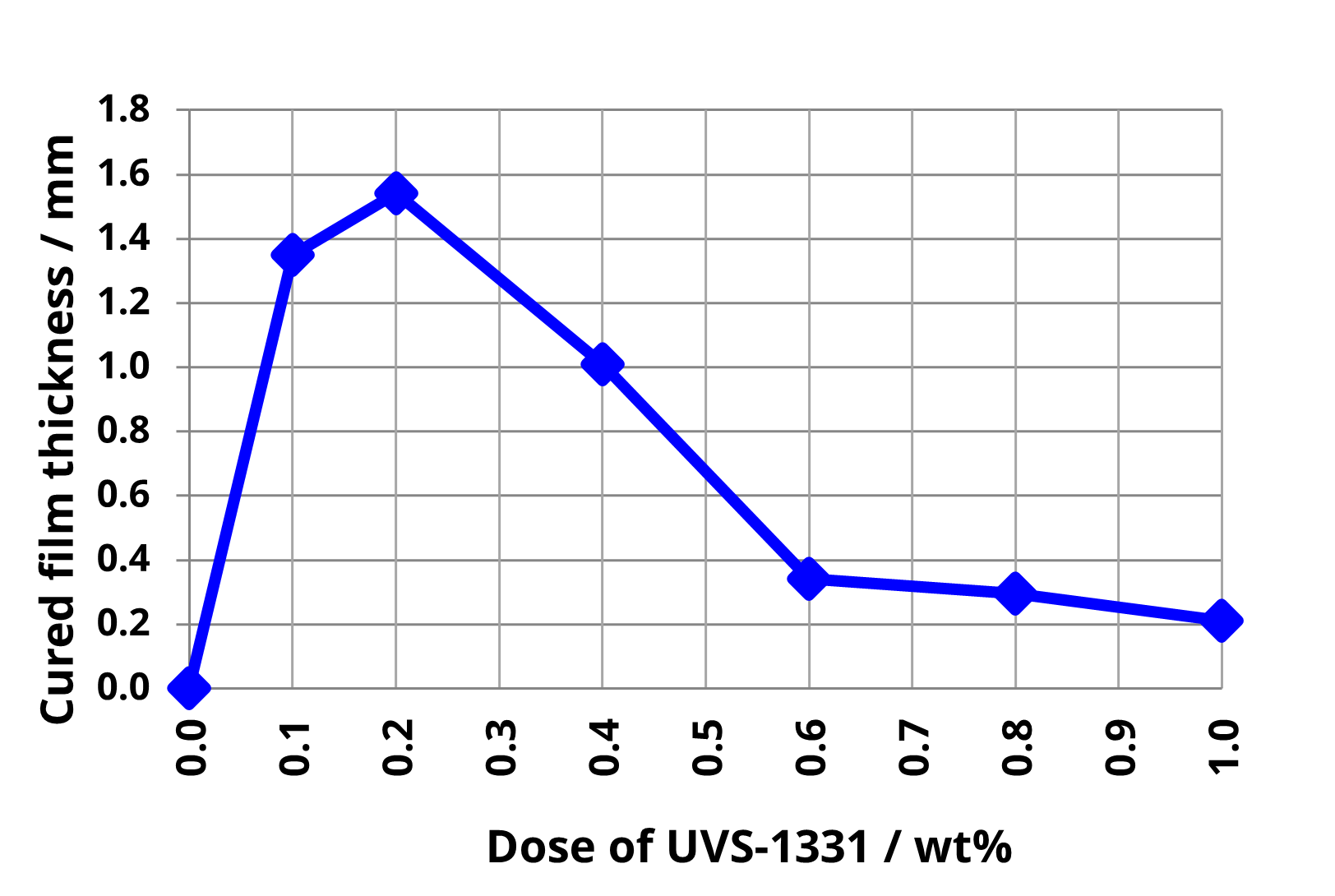

- Optimizing dose of UVS-1331 cures depth

To harden thick layer, optimizing the dose of UVS-1331 would be required.

Adding excessive dose could lead to hardening failure in the depths of layer

UVS-1101 shows a similar result as well.

<< Formulation>>

- Monomer:

- Celloxide 2021P *1 100 parts

- Photo-initiator:

- Omnicat 250 *2 2.5 PHR

- Photo-sensitizer:

- ANTHRACURE UVS-1331 0.0 – 1.0 PHR

Curing condition

Light source : 405nm UV-LED

Intensity : 50 mW/cm2

Duration : 120 sec

Atmosphere : Air at r.t.

*1 : Daicel Corporation *2 : IGM Resins B.V

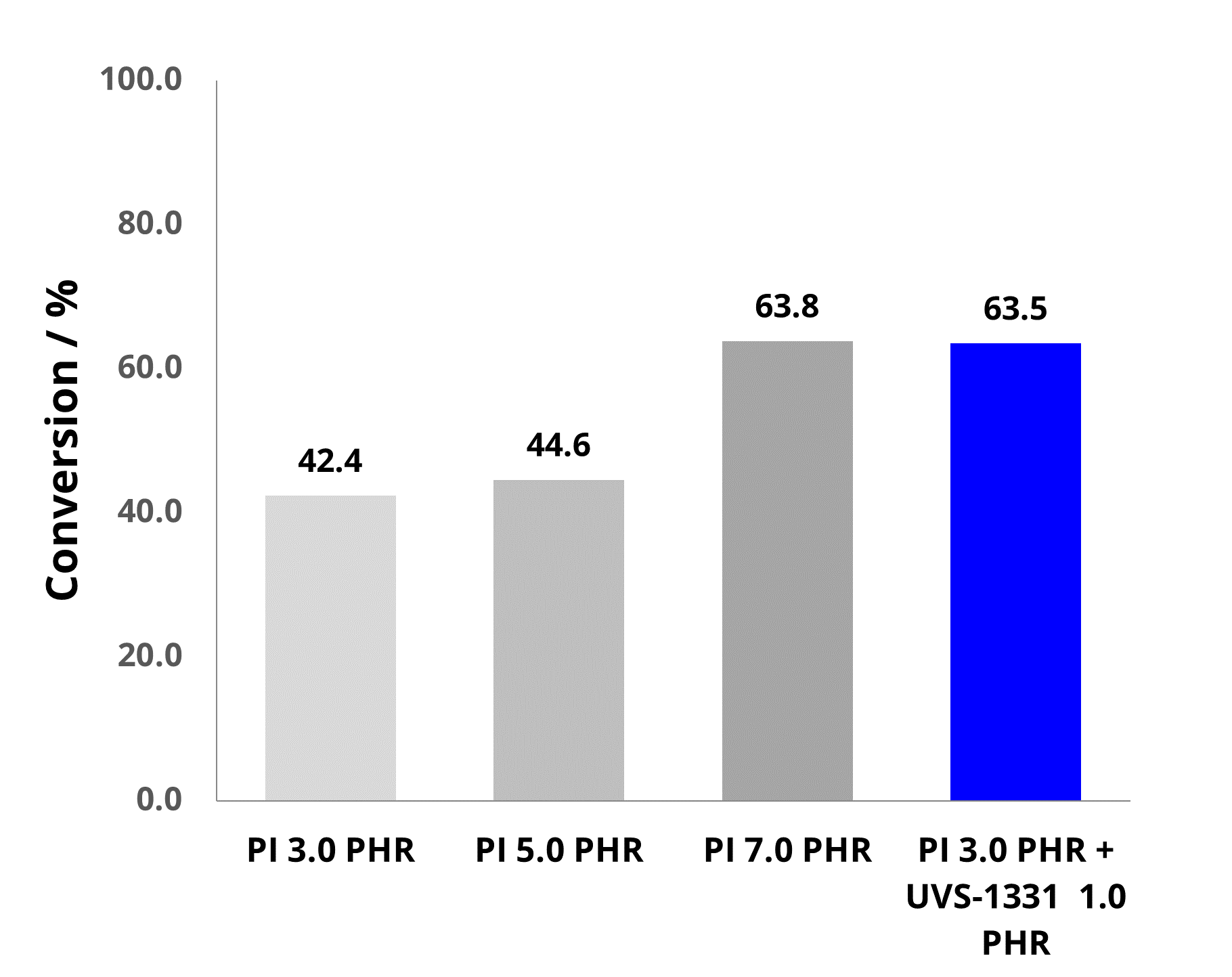

- Sensitize a polymeric Type II initiators for food packaging inks

UVS-1331 and 1101 is listed as Part B in Swiss Ordinance (RS 817.023.21 Annex 10).those are capable of reducing the dose of initiator and/or amine synergists.

UVS-1101 shows a similar result as well.

<< Formulation>>

- Monomer:

- TMPTA 100 parts

- Photo-initiator:

- Omnipol BP * 3.0, 5.0 or 7.0 PHR

- Photo-sensitizer:

- none or ANTHRACURE UVS-1331 1.0 PHR

Curing condition

Light source : High Pressure mercury lamp

Intensity : 135 mW/cm2

Duration : 10.0 sec

Atmosphere : Air

Average thickness : 30 μm(Spin Coating)

* IGM Resins B.V.

- UVS-581 CLOSE

Sensitize photo-initiator in the range from 350 to 405nm

Less yellowing because of a sharp cut-off peak at 395nm

Wide range of options for sensitizable photo-initiator

Compatible with LED wavelengths

Conjunctive use of UVS-1331 or UVS-1101 to match various wavelengths of light sources

| Product name | ANTHRACURE™ UVS-581 |

| Swiss Ordinance SR 817.023.21 |

ー |

| Delivery Unit | 10kg |

- UV-Vis Spectrum Chart

Concentration : 10 ppm in CH3CN

Optical path length : 10mm

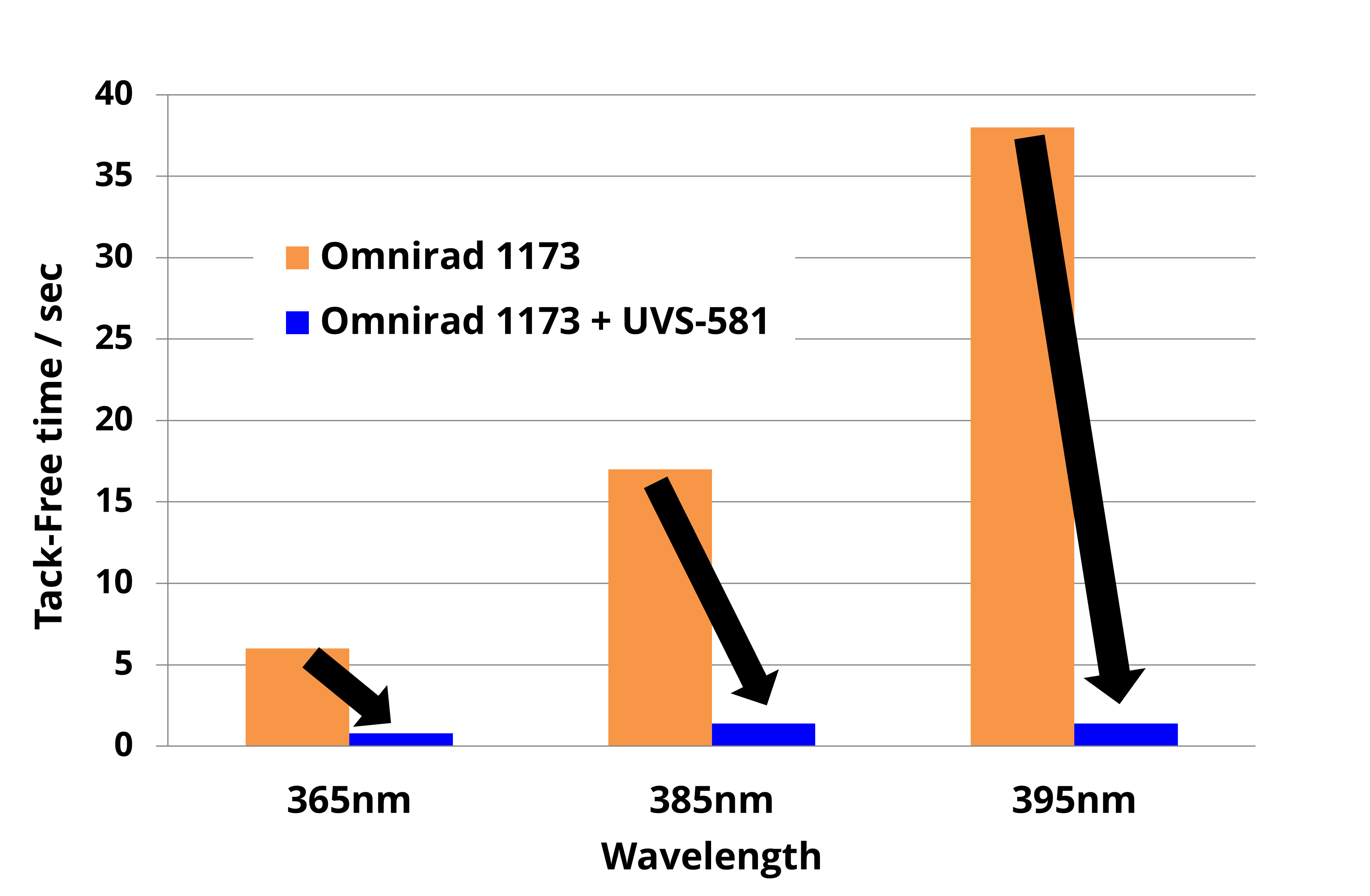

- Improving curing rate under different LEDs

UVS-581 speed cure under different wavelength of LEDs

<< Formulation>>

- Monomer:

- Viscoat #400 *1 100 parts

- Photo-initiator:

- Omnirad 1173 *2 5 PHR

- Photo-sensitizer:

- none or ANTHRACURE UVS-581 1.0 PHR

Curing condition

Light source :

365nm UV-LED (43mW/cm2)

385nm UV-LED (43mW/cm2)

395nm UV-LED (50mW/cm2)

Layer thickness : 30 μm

Atmosphere : Air

UV curable layer covering with 50 micron of PET film and exposed to UV-LED passing through PET

*1 : Osaka Organic Chemical Industry Ltd. *2 : IGM Resins B.V.

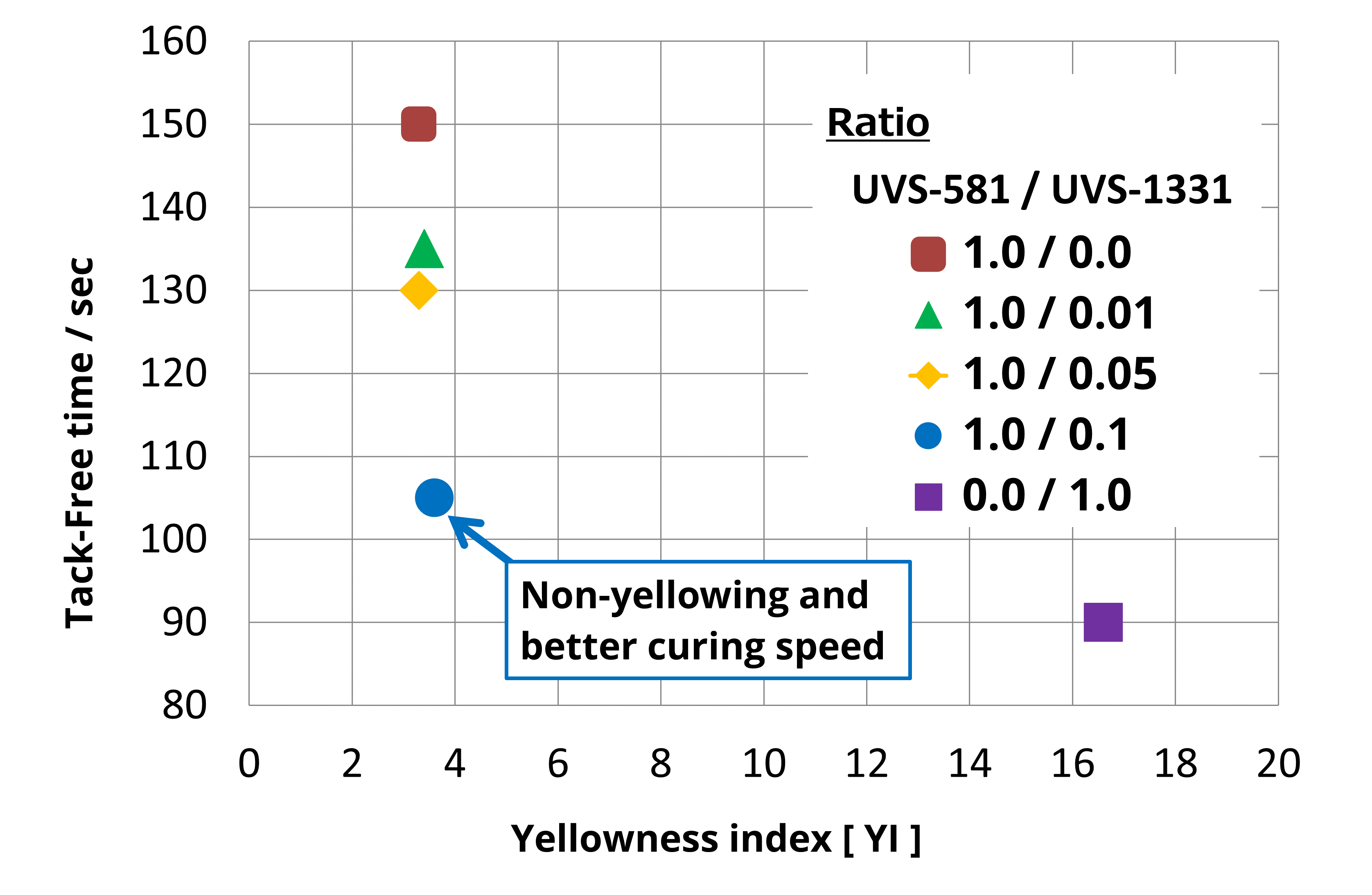

- UVS-581 to reduce yellowing

Incorporating UVS-581 into UVS-1331 contributes to reduce yellowing and enables to remain curing speed when balancing the dose ratio

<< Formulation>>

- Monomer:

- Celloxide 2021P *1 100 parts

- Photo-initiator:

- CPI-100P *2 2.0 PHR

- Photo-sensitizer:

- ANTHRACURE UVS-581 and/or UVS-1331 (referring to the explanatory note in the following graph)

Curing condition

Light source : 395nm UV-LED (50mW/cm2)

Layer thickness : 0.4 mm

*1 : Daicel Corporation *2 : San-Apro Ltd.

- UVS-2171 CLOSE

Sensitize Photo acid generators (PAGs) and radical photo-initiators under 365 – 405nm even though it’s less absorbance in its range

Solution for non-colored items

Compatible with UV LED wavelengths

Conjunctive use of UVS-1331 or UVS-1101 to give a boost to cure and to reduce yellowing

| Product name | ANTHRACURE™ UVS-2171 |

| Swiss Ordinance SR 817.023.21 |

ー |

| Delivery Unit | 10kg |

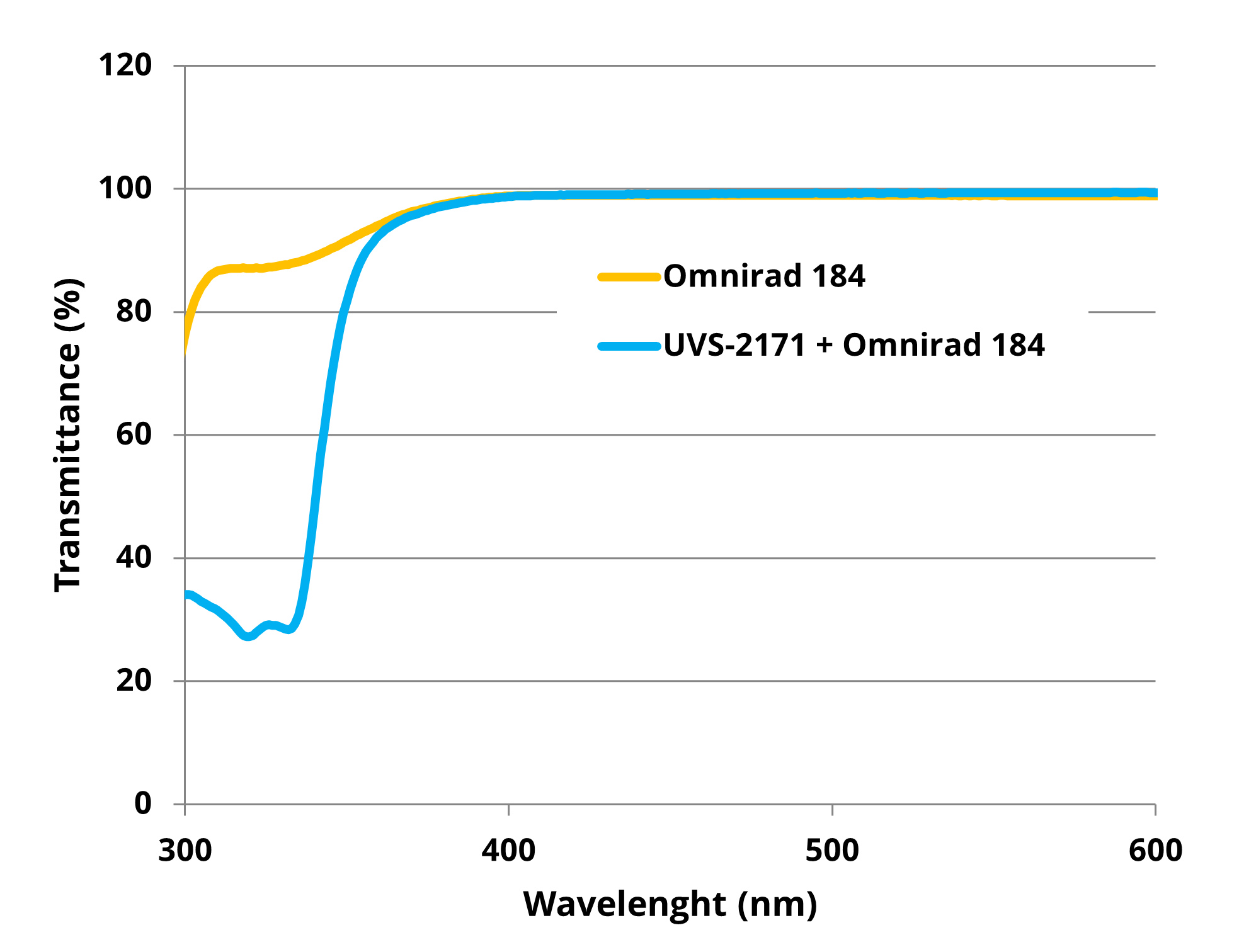

- UV-Vis Spectrum Chart

Concentration : 10 ppm in CH3CN

Optical path length : 10mm

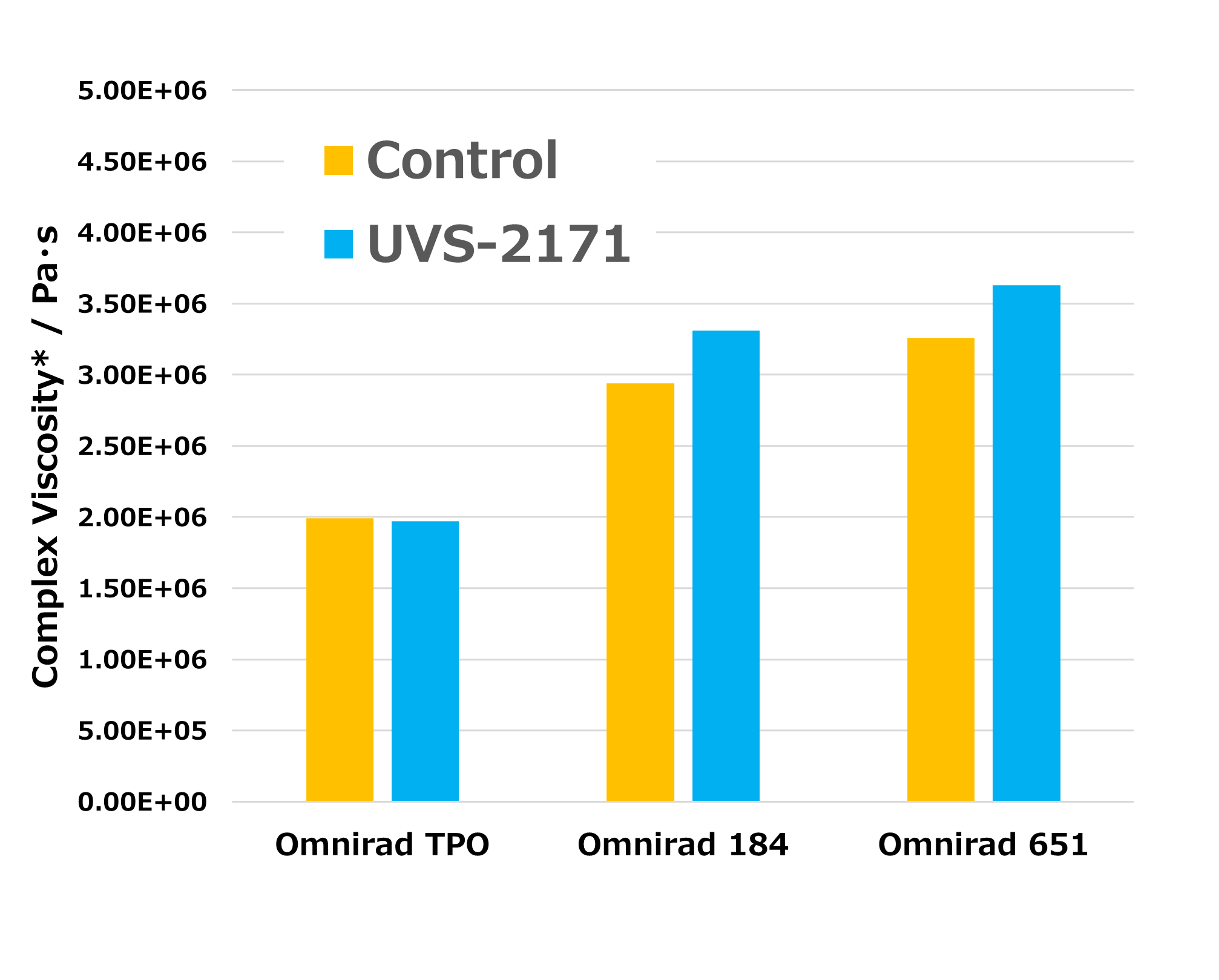

- Thick layer with high transmittance

UVS-2171 sensitizes Omnirad 184 and 651 under 365nm while remaining transparency (referring to the following YI data)

Viscosity by Photo-Rheometer and sensory evaluation

<< Formulation>>

- Monomer:

- TMPTA 100 parts

- Photo-initiator:

- Omnirad TPO, 184, 651 *1 each 5 PHR

- Photo-sensitizer:

- none or ANTHRACURE UVS-2171 0.1 PHR

Curing condition

Light source :

i line (365nm) (200mW/cm2)

Duration : 30 sec

Layer thickness : 1 mm

Temp. : 25℃

Strain : 0.1%

Frequency : 1 Hz

*1 : IGM Resins B.V.

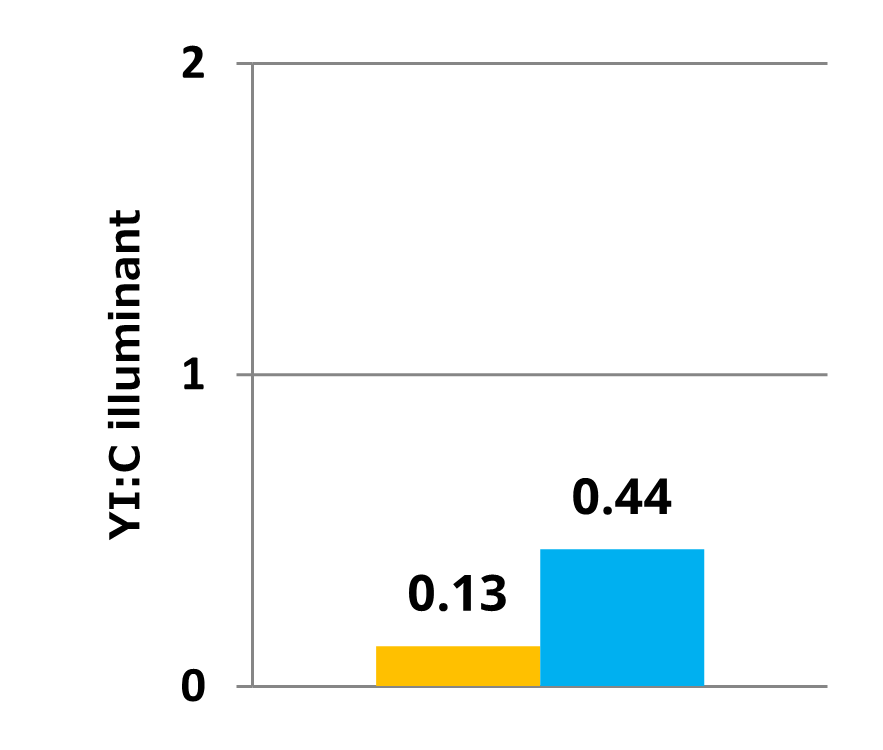

Comparison of Yellowness Index (YI)

With UVS-2171, there is no influence on visible appearance

<< Formulation>>

- Monomer:

- TMPTA 100 parts

- Photo-initiator:

- Omnirad 184 *1 5 PHR

- Photo-sensitizer:

- none or ANTHRACURE UVS-2171 1.0 PHR

Curing condition

Light source :

365nm UV-LED (1 W/cm2)

Layer thickness : 25 micron

*1 : IGM Resins B.V.

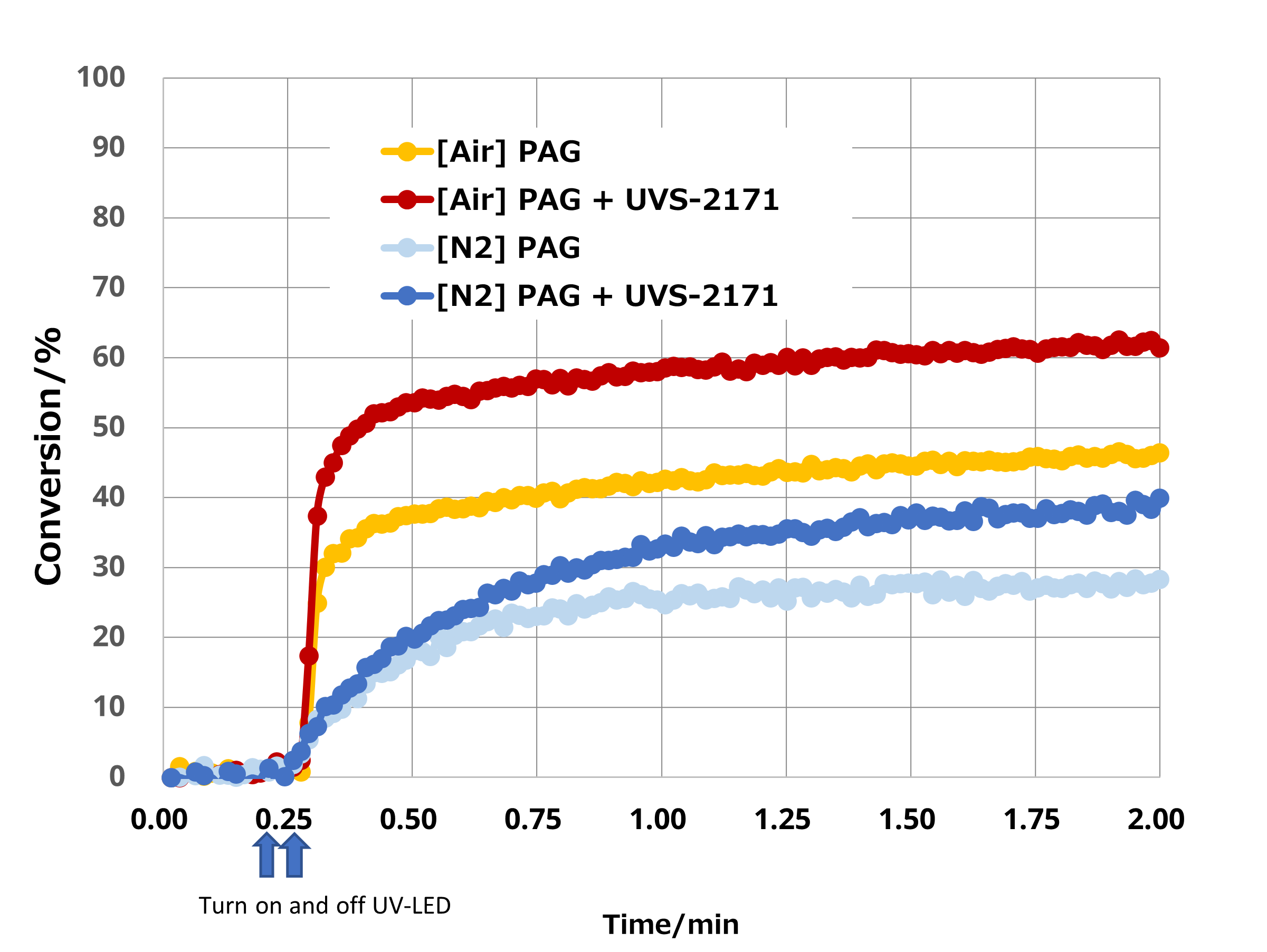

- Improve the degree of polymerization in the Air and N2

Improving conversion under different ambience

Adding UVS-2171 contributes to higher degree of polymerization under different ambient conditions

<< Formulation>>

- Monomer:

- Celloxide 2021P *1 100 parts

- Photo-initiator:

- CPI-100P *2 3.0 PHR

- Photo-sensitizer:

- none or ANTHRACURE UVS-2171 2.0 PHR

Curing condition

Real Time FT-IR

Light source :

365nm UV-LED

280mJ/cm2 (85 mW/cm2 × 3.3sec)

Atmosphere : Air and Nitrogen (N2)

*1 : Daicel Corporation *2 : San-Apro Ltd.

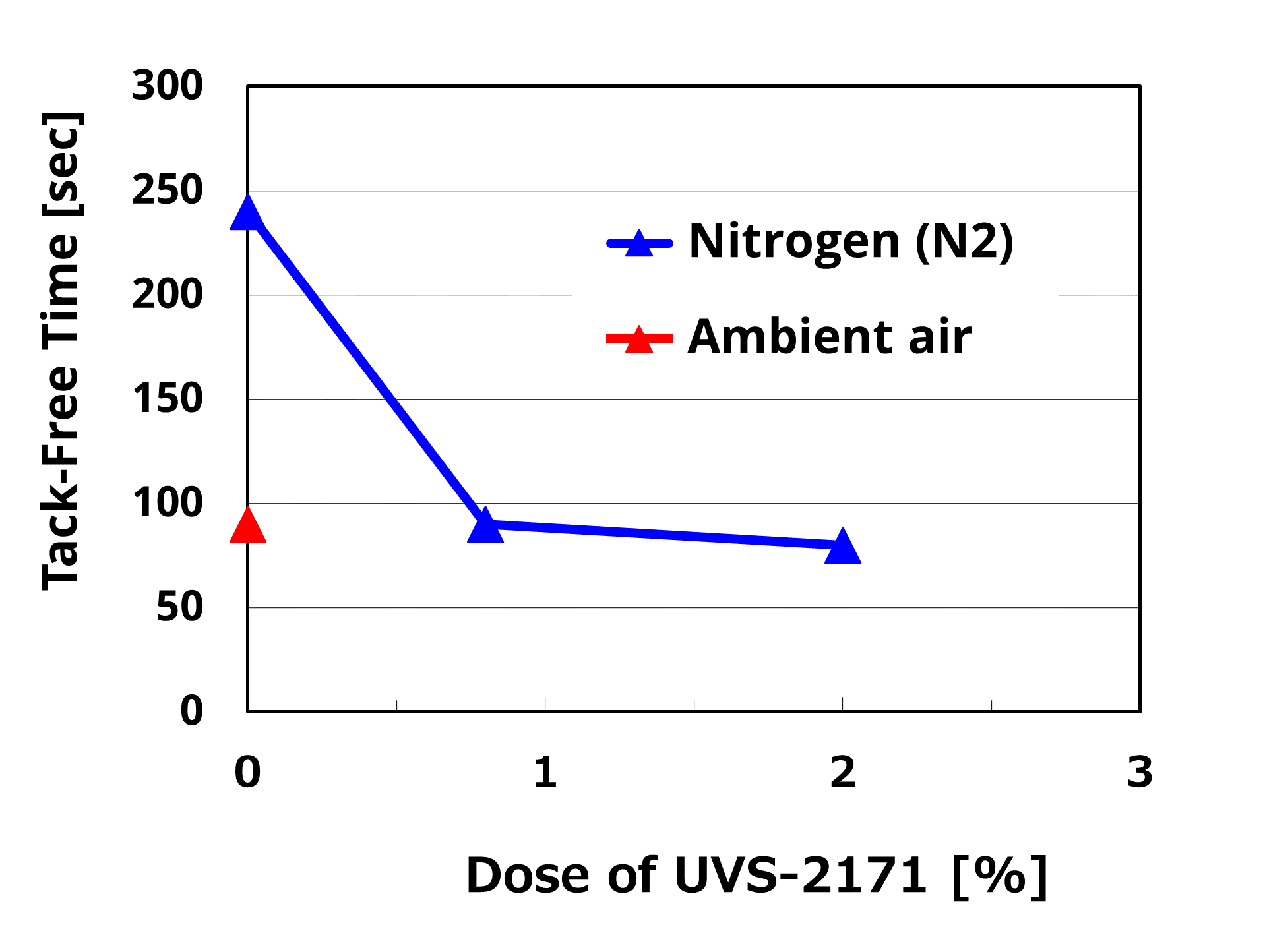

Comparison of tack-free time under ambient air and N2

When added UVS-2171, the curing rate under N2 improved as fast as it under ambient air

<< Formulation>>

- Monomer:

- UVR6105 *1 100 parts

- Photo-initiator:

- UVI-6992 *1 3.0 PHR

- Photo-sensitizer:

- none or ANTHRACURE UVS-2171 0.8 PHR or 2.0 PHR

Curing condition

Real Time FT-IR

Light source :

365nm UV-LED (< several tens mW/cm2)

Atmosphere : Air and Nitrogen (N2)

Thickness : 12 μm

*1 : Dow Chemical Company

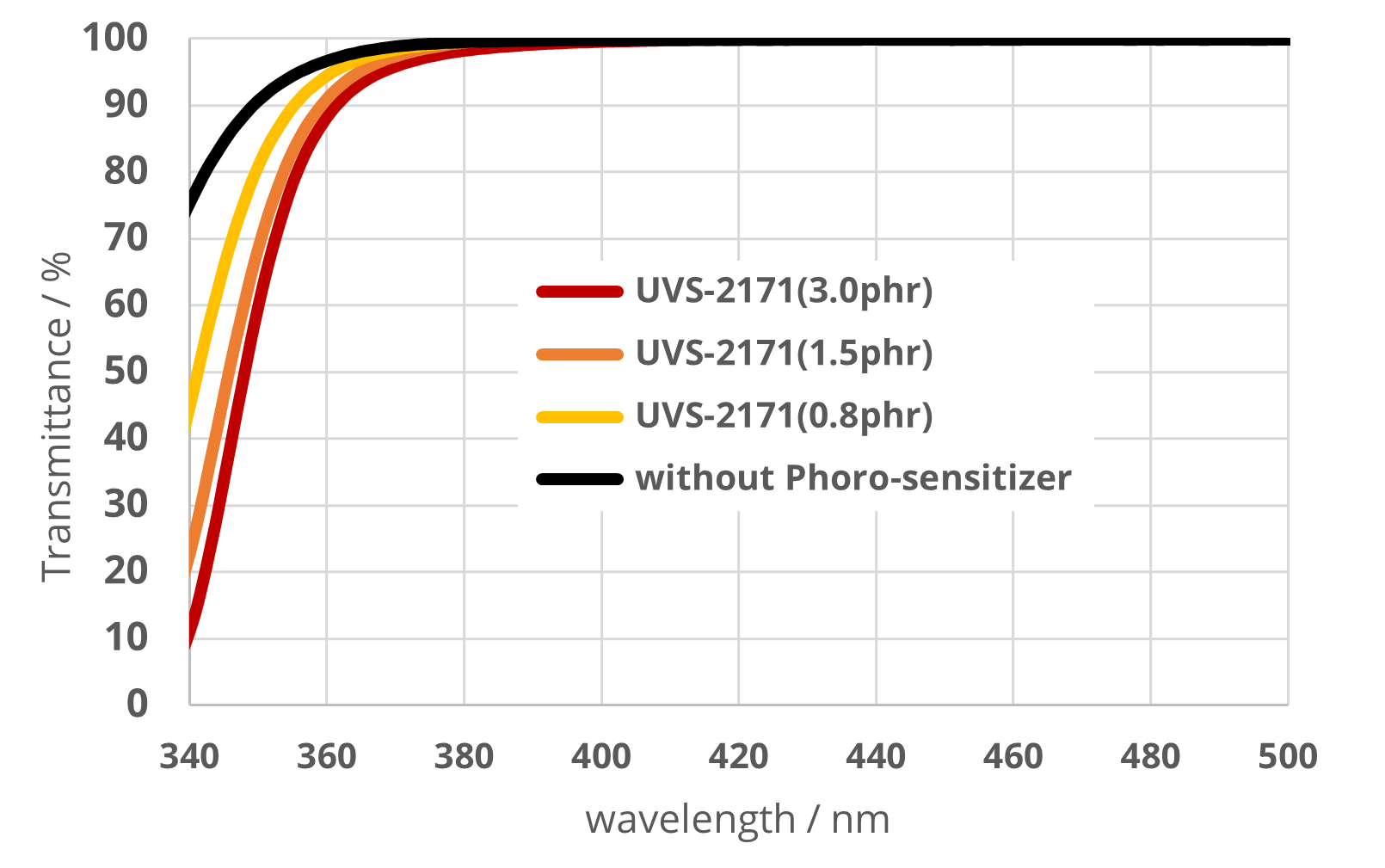

- Sensitize PAG and reduce yellowness

Sensitize PAG and remain transmittance

When added UVS-2171 in cationic system, the cured layer remains transparent appearance

<< Formulation>>

- Monomer:

- Celloxide 2021P *1 100 parts

- Photo-initiator:

- CPI-100P *2 3.0 PHR (active ingredient)

- Photo-sensitizer:

- none or ANTHRACURE UVS-2171 0.8, 1.5, 3.0 PHR

Curing condition

Light source :

365nm UV-LED (0.53 W/cm2)

Conveyer speed: about 1 m/min

Layer thickness : about 30 micron (spin-coated)

Atmosphere : Air

*1 : Daicel Corporation *2 : San-Apro Ltd.

■ Utilize UVS-2171 to reduce the yellowness of UVS-1331

| Appearance |

Test conditions; + Cycloaliphatic Epoxy Resin CYRACURE UVR-6105 *1 100 parts + Initiator : Omnicat 250 *2 2 PHR + Thickness : 500 μm + Light source : UV-LED 395nm + light intensity : 1.5W/cm2 |

||

|---|---|---|---|

| Before irradiation | 4 min. after irradiation | ||

| 0.5 PHR of UVS-1331 |

|

|

The UV curable layer color started to change in only 5 sec. After irradiation, it turns yellow gradually. (the color of mixture shows slightly yellowish before irradiation.) |

|

0.1 PHR of UVS-1331 + 2.0 PHR of UVS-2171 |

|

|

When using both UVS-1331 and 2171 the layer remains transparency in 5 sec. |

*1 : The Dow Chemical Company *2 : IGM Resins B.V.